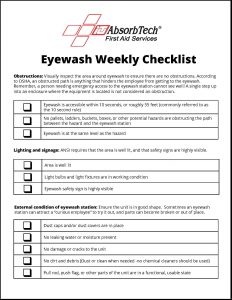

Weekly flush the eye wash station to ensure it is working properly and is unobstructed and accessible. Document the inspection below, noting any deficiencies. Fill Eyewash Station Checklist Form, download blank or editable online. Emergency Eyewash Station Weekly Inspection Checklist. Application/pdf icon.

BENEFITS Workers’ eyes are vulnerable to various hazards on the job, such as dust, pieces of material shooting out of equipment and splashes of hazardous substances. Although you should take steps to protect workers from getting anything in their eyes, something could still happen. In that event, it’s critical the worker acts quickly and flushes out his eyes. That’s why you should have emergency eyewash stations and conduct regular inspections to ensure that they’ll work properly when needed. HOW TO USE THE TOOL Adapt this checklist, which is modeled on one from Concordia University, for the requirements in your jurisdiction on eyewash stations and the instructions from the station’s manufacturer. Ensure that a competent person uses the checklist to conduct regular, such as weekly, inspections of your eyewash stations. Correct any issues or problems identified during the inspection.

The ANSI standard Z358.1-2009 requires that plumbed flushing equipment (drench showers, eyewash stations etc,) whether portable or self contained, should be visually checked to determine if flushing fluid needs to be changed or supplemented. Download camtasia studio 7 full crack mf. Our Eyewash Inspection Tags allow facility owners to track repair and maintainance of eyewash stations crucial for employees working with hazardous materials.

• Eyewash Inspection Tags are a vital part of your inspection protocol. Use these tags whenever an inspection is called for or completed.

• Write in detailed information for clear, visible messages. • Hang your tag almost anywhere with a durable reinforced eyelet. • Click on any designs below to learn more about our quick-shipping stock items.

Most Viewed Pages

- Ddp Yoga Beginners Download Free

- Eyeshield 21 Full Episodes Torrent Download

- B7722 Flash Loader Download

- Chistij Blank Pasporta Ukraini

- 600 000 Midi Torrent

- Gak Grigorjev Teoriya I Praktika Perevoda Otveti

- Pitbull El Mariel Zip

- Photoshop Cs6 Portable Rar Download

- Individualjnij Marshrut Razvitiya Rebenka S Ovz V Detskom Sadu Obrazec

- 12 Korolevstv Kniga

- War In The Pacific Admirals Edition Download

- Mannlicher Schoenauer Rifle Serial Numbers

- Boris Uvajdov Kniga Pobeda Nad Rakom